peripheral pump vs centrifugal pump|centrifugal water pump definition : retailer Peripheral pumps (also known as vortex, turbine or regenerative pumps) are able to produce high discharge pressures of other pumps and conform to the versatile operation of centrifugal pumps but, with a less .

WEBLista IPTV Canal Globo; Onde ver as listas do iptv no canal aberto globo; Lista IPTV Canal Aberto Globo ; Se você está procurando uma maneira de assistir à programação da Globo gratuitamente, a lista IPTV com os .

{plog:ftitle_list}

WEBr/babycaroline_69: Caroline Lopes / 21 years old

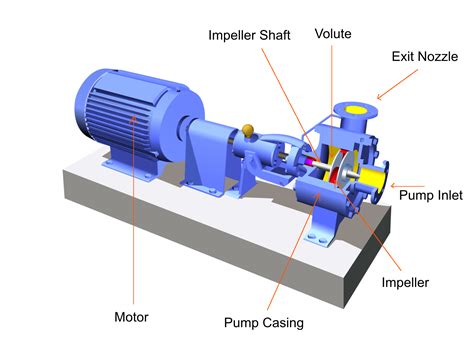

what is a centrifugal pump

The pump can be driven by an electric motor or engine. Centrifugal pumps are usually used for liquids which are low in viscosity and low in solid concentration. However, there is a centrifugal slurry pump which can move liquids with a .Peripheral pumps, also referred to as regenerative pumps (also see Side channel pumps), are centrifugal pumps whose impeller (see Peripheral impeller) rotates in a largely concentric .

z spray machine

Peripheral pump curves are steeper than centrifugal and side channel pumps as shown across which is quite different to that of a centrifugal .A peripheral pump, also called a turbine, vortex or regenerative pump, utilises a vanned impeller and is similar in concept to a side-channel pump. In terms of operation, peripheral pumps . Industrial pumping is a vast world with many different types of pumps. How do you recognise the difference between centrifugal pumps, diaphragm pumps, and high-pressure pumps?

Peripheral pumps (also known as vortex, turbine or regenerative pumps) are able to produce high discharge pressures of other pumps and conform to the versatile operation of centrifugal pumps but, with a less .In the world of water pumps, there are many different varieties from centrifugal pumps to well pumps and submersible pumps.One of the most useful are peripheral pumps – if you are unsure what these are exactly and what you .

The technical characteristics of peripheral pumps. Peripheral pumps (also known as vortex, turbine or regenerative pumps) are able to produce high discharge pressures of other pumps and conform to the . Self-priming pumps are a category of pumps designed to eliminate the need for manual priming, which involves filling the pump and suction lines with liquid before starting the pump. This feature makes self-priming pumps particularly useful when dealing with suction lifts, where the pump is situated above the liquid source.Centrifugal pumps are used in series to overcome a larger system head loss than one pump can compensate for individually. As illustrated in Figure 13, two identical centrifugal pumps operating at the same speed with the same volumetric flow rate contribute the same pump head. Since the inlet to the second pump is the outlet of the first pump .

Centrifugal pumps are also susceptible to water hammer. Surge analysis, a specialized study, helps evaluate this risk in such systems. Triplex-style plunger pump . liquid-ring pump, peripheral, traction, turbulence, or vortex pumps, regenerative turbine pumps are a class of rotodynamic pump that operates at high head pressures, typically 4 . Peripheral Self-Priming Pumps: Peripheral pumps, also known as regenerative or side-channel pumps, use an impeller with radial blades that channel fluid around the pump casing. This design creates a continuous flow and self-priming capabilities. Peripheral self-priming pumps are suitable for low flow and high-pressure applications.A centrifugal pump generates suction by spinning an internal fan. Unlike other pumps, centrifugal pumps have mechanical parts outside the Well. As a result, that makes servicing them much easier. Centrifugal pumps have limited functionality in deep wells because of . Approximately 85% of water pump designs are centrifugal pumps. This video discusses a variety of things to help you better understand centrifugal pumps, incl.

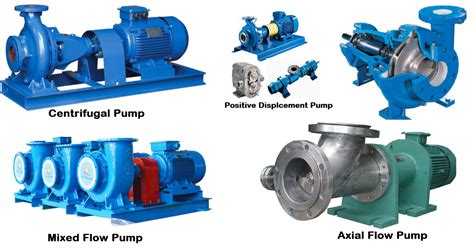

Centrifugal pumps are the most common pump type for the transfer of low viscosity fluids in high flow rate, low pressure installations, which makes them ideal for applications that require the pump to deal with large volumes. The centrifugal pump design is often associated with the transfer of water, but is also a popular solution for handling .A centrifugal pump is a machine that uses rotation to impart velocity to a liquid, it then converts that velocity into flow. Centrifugal pumps are made up of two primary components: an impeller and a casing. The rotating impeller generates velocity and the casing converts velocity into flow.A peripheral vane pump (also known as a regenerative turbine pump) is similar to a centrifugal pump, except it operates with a different style impeller. . Centrifugal pumps are not designed to handle gas in a liquid, gas in a centrifugal pump can create a significant loss in performance causing fluctuating flow, discharge pressure, and . Peripheral Pumps Peripheral pumps are a niche pump type with characteristics between centrifugal and positive displacement pumps as they can generate the high head of positive displacement pumps, with the operational flexibility of centrifugal pumps but with a lower flow rate. Their working kinetic principle is similar to centrifugal pumps.

Conventional centrifugal pumps typically operate within the range of 0.1 to 10 MPa, while high-pressure centrifugal pumps can reach pressures of several tens of MPa. The pressure range of positive displacement pumps is typically between 0.1 and 10 MPa. Viscosity: Centrifugal pumps are suitable for fluids with a viscosity range of 0.3 to 5000 .Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. . is the peripheral circumferential velocity vector. Since no pressure forces are created on cylindrical surfaces in the .A. Centrifugal Pumps: Operating Principle: Centrifugal pumps function by exploiting centrifugal force created by the revolving impeller. As the impeller rotates, the fluid is pushed outward from the center towards the casing walls. .

In the world of pumps, axial flow pumps and centrifugal pumps are two common types with unique characteristics. Their different working principles, fields of application, and advantages and disadvantages make it . A centrifugal pump uses an impeller, which rotates at a specific speed to generate a centrifugal force that will displace the fluids and allow them to move into an outlet. At the same time, it has an eye, which is necessary to .The close tolerances between the impeller and casing do not allow the passage of solids so peripheral pumps can only be used with ‘clean’ liquids. How does a Peripheral Pump work? The key component of a peripheral pump is its impeller. Unlike a centrifugal pump, this consists of a large number of small vanes cut into the impeller’s outer rim.Request a Quote. Centrifugal and positive displacement pumps are powerful tools that can move fluid through complex industrial and municipal systems. But it’s essential to choose the right equipment for your facility’s needs. Here, we’ll discuss the differences between the two pump types, the fluids they can handle, and some of the most popular applications of each pump.

Water Pump vs. Booster Pump A Comprehensive Guide I. Introduction A. Explanation of the importance of water pumps. Water pumps play a vital role in various aspects of our lives, even though they often operate behind the scenes, out of sight and out of mind. These essential mechanical devices are designed to move water from one place to another, ensuring a steady . They have many moving parts, including bearings and seals, which require regular maintenance and replacement. However, centrifugal pumps are generally easier to repair since many components are designed to be replaceable. In conclusion, both peripheral pumps and centrifugal pumps have their advantages and drawbacks depending on the application. Introduction A peripheral pump is a kind of widely-used pump characterized by its utilization of a rotating impeller to generate pressure, facilitating the movement of water . Functioning as a centrifugal pump, a peripheral pump finds its niche in low-flow, high-pressure applications, notably catering to tasks such as irrigation, water supply . Peripheral Pumps. Peripheral pumps are a type of centrifugal pump that operate at lower flow rates and higher heads compared to other centrifugal pump designs. They are characterized by their unique impeller design, which features a large number of small vanes arranged around the periphery of the impeller.

For example, thick food items like honey can create friction within the impellers and can reduce the performance of the pump. Centrifugal pumps are ideal for the following industrial systems: - Industrial water supply - Seawater transfer - Air conditioning systems - Industrial boiler feed - Thin fuel transfer - Industrial washing - Firefighting .We would like to show you a description here but the site won’t allow us.

This video is an overview of the main differences between a regenerative turbine pump vs a centrifugal pump. Focusing on impeller design, efficiency, and cav.Centrifugal pumps can be designed to handle more air if required. Viscous drag pumps can handle large quantities of air. . Peripheral (regenerative) pump: also known as regenerative or regenerative turbine pump. These are low capacity (150 gpm or 34 m3/h) high head (5400 ft or 1645 m) pumps. .

types of centrifugal pumps

peripheral water pumps

z sprayer

peripheral pump definition

MForce (Palmela) Pinhal Novo, Quinta do Anjo. Quinta do Anjo - Makro de Palmela, Parque Estacionamento Exterior (Pinhal Novo, Quinta do Anjo) (Palmela) 912 443 219 (Chamada para a rede móvel nacional) Site. É proprietário desta empresa? Clique para Editar. Informação. Marcações: 210 115 017.

peripheral pump vs centrifugal pump|centrifugal water pump definition